Autoclave pouches inside a Tuttnauer Elara tabletop autoclave

Autoclaves can be found in dental clinics around the world. An autoclave enables oral health professionals to carry out their work whilst minimizing the risk of cross infection to themselves and their patients as a consequence of non-sterile instruments being used in the delivery of treatment.

A minimum requirement for every autoclave, which some say is a “Colloquial term for a steam-under-pressure sterilizer”[i] is that they must meet the Australian & New Zealand standard AS/NZS418.

The ADA guidelines for Infection Control map out the three types of autoclave classes: Class N, Class S and Class B. In summary;

A type ‘N’ sterilizer is a compact and simple unit which is only suitable for sterilizing unwrapped, solid items.

A type ‘S’ sterilizer can only sterilize loads that the manufacturer states the machine can process. The machine manual should indicate what can and cannot be processed, or the manufacturer themselves will have this information. If you are unable to clarify this then you must treat the machine as a type ‘N’ sterilizer and process only non-wrapped solid instruments.

A type ‘B’ sterilizer is able to process more difficult loads such as wrapped items and hollowware. It is able to do this as the machine removes air from the chamber by creating a vacuum before applying steam to the load[ii]. A number of different cycles may be provided. Each cycle should be fully validated and used in accordance with instructions provided by both the sterilizer and instrument manufacturer.

A Class B autoclave is recommended for dental clinics and practices by autoclave manufacturers as they offer great flexibility and a wide range of settings (including unwrapped, wrapped, hollow and delicate items). Throughout this article we will be discussing how the Class B autoclave functions and operates and why it is the best option for dental surgeries.

Class B Tabletop Autoclaves

Class B autoclaves are different to Class N and Class S autoclaves because they use a vacuum pump to both remove air and to dry the load. Class B autoclaves are able to remove more than 99% of the air inside the chamber, ensuring no trapped air that would prevent steam from reaching the load surface, thus killing microbial life on the load, without the need for external hookups to water or steam (some tabletop autoclaves are connected to water pipes for auto-filling, so operators don’t need to fill them).

Class B autoclaves are great space-savers built for high performance. They are microwave-sized autoclaves that fit easily on the counters of busy clinics and dental offices and are essentially plug and play and user friendly. Available with a variety of chamber sizes depending on the needs of your practice and the capacity to autoclave hollow and solid instruments pouched and un pouched products the Class B, because of the functionality of the product is the top-of-the-line of tabletop autoclaves and a minimum requirement for most dental practices.

Tuttnauer Elara 9 (19L), Class B Tabletop Autoclave

How Does the Class B Autoclave Work?

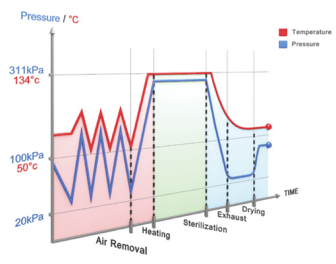

- First we remove the air. How? By use of a vacuum pump, the Class B autoclave uses vacuum pulses to extract the air in the autoclave chamber. This process is able to remove more than 99% of the air inside the chamber.

Let’s say we are going to use three pulses to extract the air. The first pulse will extract about 80% of the air, leaving 20%. Then in the second pulse, 80% of the 20% remaining will be extracted (leaving 4% of the initial air). And finally the last pulse will remove 80% of the last 4% of air, which brings us to the low overall number of 0.8% of air left in the chamber. In other words, each pulse extracts 80% of the air, so that with each pulse, that number gets much smaller, leaving us with a final number of 99% air removal in total. This whole process is called fractionated pre-vacuum air removal. It eliminates air pockets and thus improves the penetration of the steam into the deepest point of the load.

In this graph you can see the pre-vacuum air removal pulses (in pink) achieved by the built-in vacuum pump

- After the vacuum pulses have removed almost all of the air inside the chamber, the pressure and temperature increase.

- We have now reached the sterilization stage where the temperature and pressure are held constant for the duration of the sterilization time, also known as holding time. This is the phase when the actual sterilization takes place.

- Next the exhaust valve releases the pressure to atmospheric pressure.

- The last phase is the drying phase in which the load is dried completely. Again we use the vacuum pump, but this time the vacuum pump sucks out the moisture on the load. How? By decreasing the pressure to lower than atmospheric pressure, we create a vacuum inside the chamber and reduce the temperature to lower than the boiling temperature of 100℃. This lower temperature makes the water evaporate into a gas, which is then sucked out by the vacuum pump, and voilà, the load is dried!

At this point, sterilization is complete, the load is dry, and the autoclave is safe to open.

Wet pack after steam sterilization

A wet pack at the completion of the sterilization process means there are millions of microorganisms that can breed and multiply rapidly and that the objects are unsterile and should never be used for a procedure.

There are many reasons behind the wet pack occurrences after autoclaving like poor quality of wrapping materials, poor loading and packaging technique, poor steam quality, sterilizer malfunction and there may be design related problems in the sterilization area.

The cause of a wet pack after autoclaving is a significant productivity issue for the dental practice. The work has to be done twice, the work load is increased, time and effort has been wasted and could have been used elsewhere, and there is an increased cost, a risk of potentially contaminated instruments causing an infection risk to the patient and staff and delayed or cancelled appointments.

Wet pack scenarios can be avoided by using good quality water to generate steam, performing periodic maintenance of the Autoclaves, avoiding overloading the sterilizer, allowing adequate post sterilization time to cool down the materials to room temperature, using good quality wrapping materials, and properly maintaining temperature and humidity of the sterilization area.

Autoclave Cycles

There are generally two cycles for autoclaving in a Class B tabletop autoclave:

- The standard cycle lasts about three minutes and reaches 134℃. This cycle is intended for standard materials like glassware or metal solids, hollows, porous items and textiles.

- The delicate cycle lasts fifteen minutes and operates at the lower temperature of 121℃. This cycle is designed for delicate materials like plastics and other delicate items that would not be suitable for the standard cycle.

Be Ready to Use Your Class B Tabletop Autoclave

Let’s review what we just learned about Class B autoclaves. We explained that the main advantage of Class B autoclaves is the use of a vacuum pump for extracting air before sterilization and drying the load after sterilization. We showed how the Class B autoclaves use a set of pulses to extract about 99% of the air inside the chamber, called fractionated pre-vacuum air removal. We looked at each step in the autoclaving process to understand exactly what happens inside the chamber when the cycle takes place. And finally, we described two common cycles, the standard and delicate cycles, and for which materials we would use each of them.

Autoclave Sterilisation series previous articles:

Part 1 - Microbiology and the Spread of Germs

Part 2 - Preventing the Spread of Infection in Dental Practices

Part 3 – What is an Autoclave?

Part 4 – Basic Concepts of Steam

Part 5 - Benefits of Steam Sterilization

Check out the Autoclave Sterilisation Basics series from the Sterilisation and Infection Control blog by Tuttnauer.

References

[i] https://www.gallay.com.au/blog/autoclaves/which-autoclave-is-best-for-dental-clinics-australia

[ii] http://prosystem.euronda.com/what-is-the-best-autoclave-for-a-dental-practice/

.png)